After you’ve been using a CNC router for a while, you begin to look for ways to make your life even easier (as if having a robot do work for you wasn’t making it easy enough). For me, sanding is a necessary evil. Plywood is especially prone to fuzzy edges and chipped veneer both making your job take longer. After the CNC has done it’s work you are left with lots and lots of sanding to get those edges looking nice.

Here are a few tips to cut down on that pesky cleanup time.

First off, make sure your bits are sharp. Your bits can churn through hundreds of feet of cutting in no time and you shouldn’t be surprised at how quickly they dull. Nothing compromises your edge quality and sharpness of cut like a dull bit. As soon as you see your cuts getting fuzzy, it’s time for a sharp bit.

Secondly, consider whether you are performing a conventional or climb cut. I have found climb cuts perform better in plywood than conventional cuts. To see for yourself, compare your parts to the waste material. If the waste material has a cleaner edge than your part does, you should switch the direction you are moving from conventional to climb or vice versa.

Finally, consider the bit you are using. I have fallen in love with compression spirals like the Amana 1/4″ and 3/8″ bits from Toolstoday.com. Upcut bits are great for clearing chips and preserving the veneer on the bottom of your sheet goods. Downcut spirals are great for a clean top edge. Want a clean edge on both top and bottom? You’ll need a compression spiral.

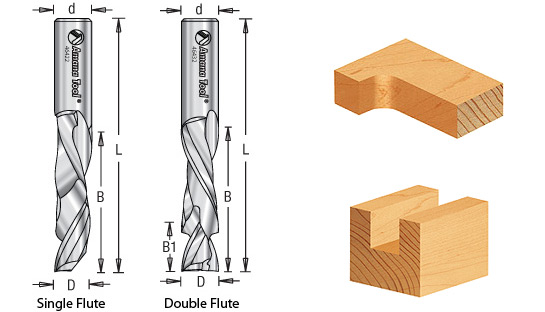

These bits combine the benefits of an up and downcut bit in one. The end of the bit (B1) is shaped to pull chips up and the rest of the bit cuts down. The result is a bit that doesn’t chip the veneer on either face of your plywood or laminated sheet goods.

I’ve been using these Amana bits for a few months now and I love them. They have become my goto bit. While they may be a bit more expensive than your standard single direction bit, the time saved in sanding and cleaning up ragged edges more than makes up for it.

Can you plunge through material with a compression spiral or are they only used on cleaning up an “open” edge.

You can plunge with a compression bit, although you should not use it for drilling holes. The compression bit’s shape does not allow chips to evacuate and can easily burn and start fires. This can be an even larger danger on vacuum tables since air may be drawn past an ember feeding it oxygen.